When a pipe is too damaged for rehabilitation, pipe bursting offers a trenchless alternative to traditional dig-and-replace. TrenchFree uses pipe bursting to replace failed pipelines by fracturing the existing pipe outward while simultaneously pulling a new pipe into place—all through small access pits rather than continuous trenching.

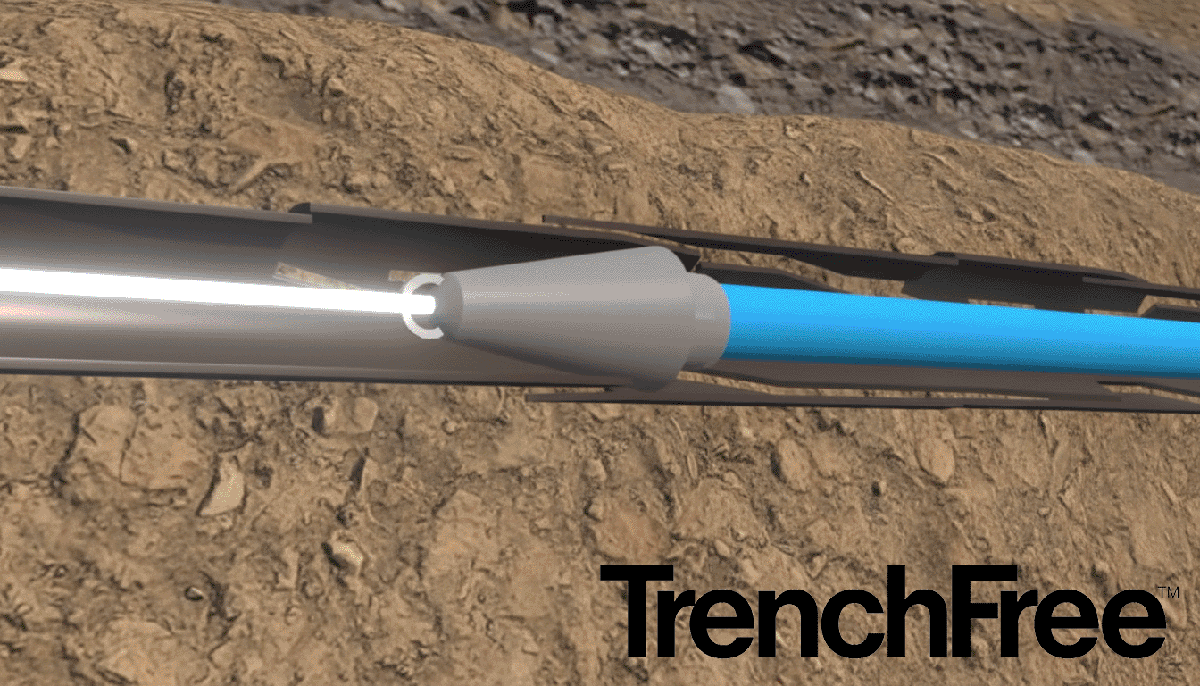

A bursting head is pulled through the existing pipe, breaking it apart and pushing fragments into the surrounding soil. Immediately behind the bursting head, a new HDPE pipe is pulled into the void, creating a seamless replacement line in a single pass.

Pipe bursting works best in stable soil conditions and requires adequate clearance from adjacent utilities. Our team evaluates each site to determine whether bursting or another trenchless method is the best fit.